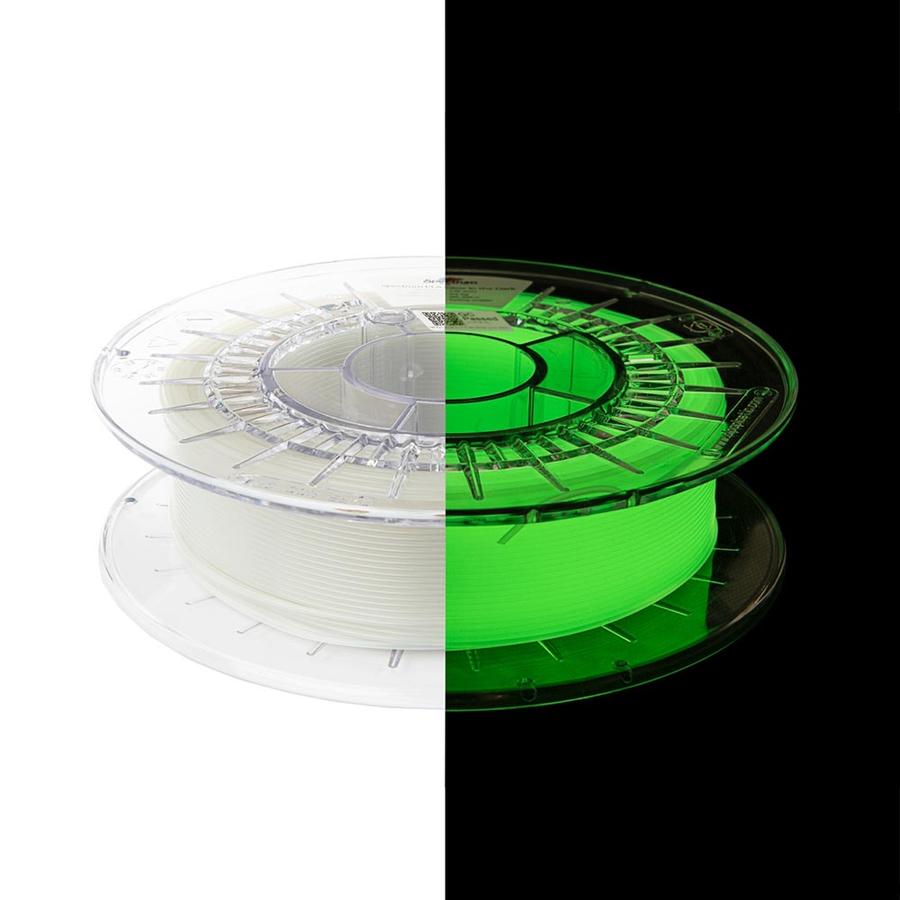

Spectrum PET-G Glow in the Dark YELLOW-GREEN 1.75mm 500g

Unbelievably strong after-glow effect

PET-G Glow in the Dark / in 1.75mm / 500g and 1000g

- Manufacturer: Spectrum Filaments

- Manufacturer number: 80536

- EAN: 5903175652966

- Item number: 36120

- Availability: from stock > delivery time 1-3 working days

Spectrum Filaments PET-G Glow in the Dark - Unbelievably strong after-glow effect

Spectrum PET-G Glow in the Dark is a PET-G-based filament blended with a concentrated phosphorescent pigment which causes the phosphorescence effect. Accordingly, once the printed items are exposed to an external light source, they will emit their own light. The material has all the typical characteristics of the pure PET-G ? the added pigment has a neutral impact on the material’s properties.

The addition of a phosphorescent pigment to PET-G provides for the following properties in printed items:

- The capability to emit own light after prior exposure to an external source of light, and

- The possibility to ?control? the light intensity of printed items by adjusting the wall thickness and filler density.

Tip: To achieve a stronger and longer lasting glowing effect, leave the model exposed to light for a longer time. The presence of phosphorescent pigment may also cause the wear of brass nozzle; thus, it is recommended to use stainless steel nozzles for prolonged application of Spectrum PLA Glow in the Dark.

Key features

- unbelievably strong after-glow effect

- high aesthetic surface quality

- warp-free printing

- perfect layer adhesion

Applications

- production of items with major ornamental and artistic effects

- production of items to help identify emergency exits for power outages

- advertising and broadly defined decoration industry

- manufacturing of various souvenirs, luminous pictures, glowing gadgets and figurines

Very good mechanical properties of Spectrum PET-G Premium combined with its chemical resistance determine the application of this material for the manufacturing of items with a relatively high dimensional accuracy and stability of both shapes and mechanical properties. Accordingly, these are mainly gear wheels and slide bearings subject to relatively high static loads in an aqueous environment. PET-G is also used to manufacture semi-transparent enclosures and backlit sections of various boards and signs

Packaging

Filament is reeled on the neat, transparent spool. Each spool contains information on the type of material, diameter and recommended printing temperature. Filament is vacuum-packed with a moisture absorber. Whole product packed in the original, folied Spectrum Filaments packaging.

VERIFY YOUR SPOOL – the most precise quality control system on the market

Filament for 3D printers is manufactured by the method of free extrusion, which is one of the most difficult processing techniques by extrusion, due to the particularly significant impact of process parameters on product dimensions and material homogenization.

During the production each 1mm of Spectrum Filament is being continuously measured in 2 axes with ±0.8µm accuracy, which allow obtaining a high-quality final product. To prove this, Spectrum Filaments, as one of the few manufacturers in the world, has introduced the possibility of online presentation, individually for each manufactured spool:

- the course of diameter on the entire length of the spool,

- mean diameter,

- ovality,

- standard deviation.

Precise survey guarantees that Spectrum Filaments products meet rigorous market requirements.

- Material

PET-G - Printing temp.

230 - 255 °C - Heatbed

60 - 80 °C - Surface

not necessary, Magigoo and BuildTak recommended - Filament diameter

1,75 mm - Filament Net weight

500g / 1000 g - Gross weight

900g / 1470 g - Storage

dry and cool

- Manufacturer

- Spectrum Group Sp. z o.o.

- Parkowa 85, 05-806 Pecice, Poland

- office@spectrumfilaments.com

- https://spectrumfilaments.com/